Manufacturing of Flexible Packaging bags for Commodities are done with 2 Roto Gravure Printing Machine

- Can use upto 8 colours

- Prints at 200mpm

- Auto registration control

- Auto splicing

- Prints on Pet/Ldpe/Cpp/Bopp/Paper

Manufacturing of Flexible Packaging bags for Commodities are done with 2 Roto Gravure Printing Machine

Multilayer Blown Film (Make : Windsor)

4 Stack Flexo Printing Machine

Solvent Based Lamination

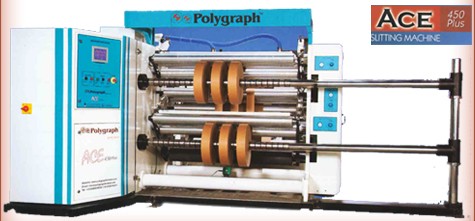

2 Slitting & Rewinder